- Joined

- May 9, 2017

- Messages

- 149

- Reaction score

- 60

- Age

- 50

You could cut down the LED's from 8 to 6. I only used 8 as that was the neopixel board i had. This would save some space and pins.thanks for chopping)) chop chop. i like this english word. it remind me of something. chop chop chop.

LM4040 is 1% accuracy. you don't want to use additional voltage reference ic? then it need to pull one pin header from vcc of regulator. let me know.

one single 0805 led consume about 20-25ma. so 160-200ma.

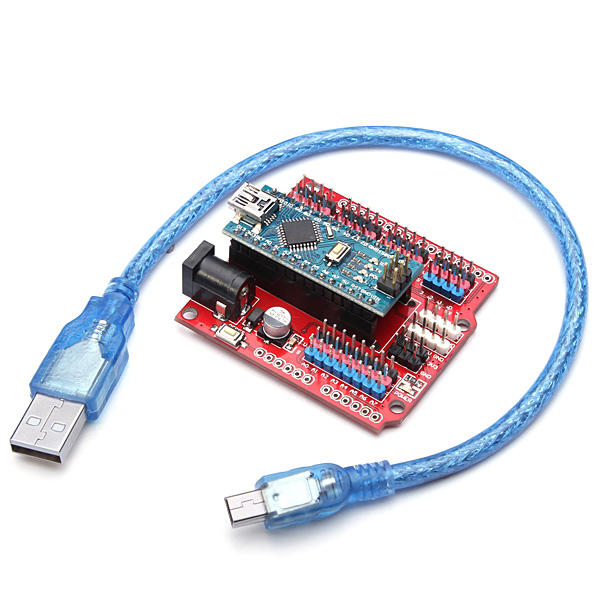

I checked pins out and allocate them as follow.

led1 -> D6, led2 -> D7, led3 -> D8, led4 -> D1, led5 -> D2, led6 -> D3, led7 -> D4, led8 -> D5

then 4 pins(D4,D3,A7,D13) are still available. but one of them(D13) is allocated to builtin led as we know. if you give up builtin led. it is possible to put 4 bits dip switch within board. if not, 3 bits. and pull down is easier to wiring than pull up in this case. need to change code.

about pcb manufacturing, 2 oz is usually 2-3 times more expensive than 1oz. also they have same pricing policy for size out of 100x100mm. so i will try to stay with 1oz and smaller than 100mm.

Have you used D9 for the Neopixel? A 3 DIP switch (or 5 if you dropped a couple of LEDs) would still be useful and leave D13 for the I2C flickering (showing coms working etc). If you turn on the internal pull up resistors in code then the DIP switches only need to be connected to the inputs and ground and no other resistors are needed.

Since the Pro Mini doesn't have an exposed vref then the 5V regulator is all that is needed to power the board and will supply its own reference voltage. I would still use a 1A or higher voltage regulator to make sure its not operating near its max rating.

Even if the 2oz board is twice the price it will make it easier to allow the required current to flow and help get the size of the board down with track size. In the scheme of things this will be a small one-off cost and allow a bit of a safety margin.