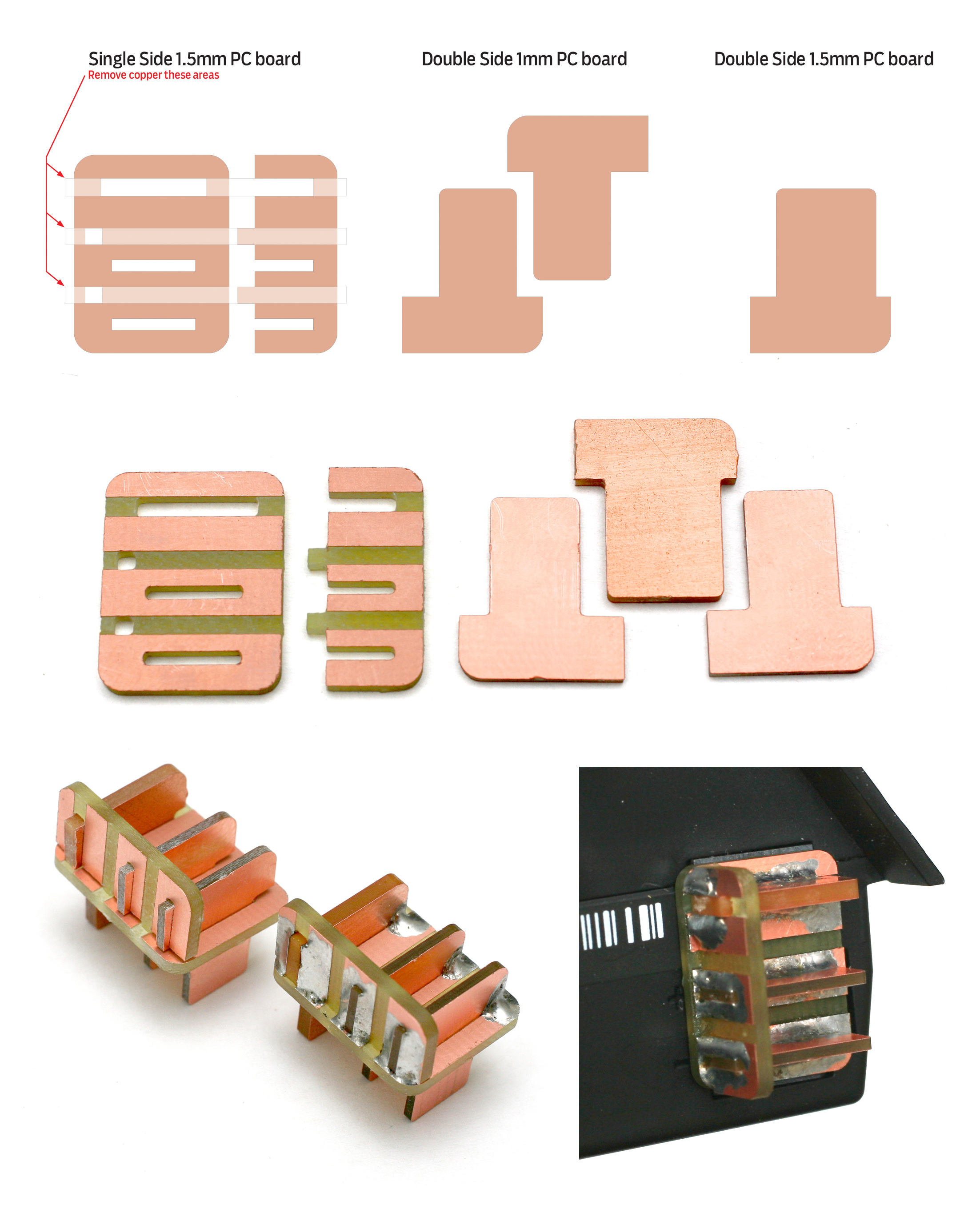

Hi everyone,

We all know the battery connector is hard to come by in reasonable quantities and prices, so I whipped this up. Forgive my sloppy solder job. The top and bottom of the main power tabs are connected, while the top data tab is separate. I think this is only 1oz copper clad board, maybe the people here with more electrical knowledge can advise on whether that's enough for the current requirements of charging the batteries.

I can make these in modest numbers, just cutting the boards and let people do the soldering. I don't want to try to make hundreds and hundreds, but it doesn't seem like that would be necessary.

Let me know what people think and what the interest level is.

We all know the battery connector is hard to come by in reasonable quantities and prices, so I whipped this up. Forgive my sloppy solder job. The top and bottom of the main power tabs are connected, while the top data tab is separate. I think this is only 1oz copper clad board, maybe the people here with more electrical knowledge can advise on whether that's enough for the current requirements of charging the batteries.

I can make these in modest numbers, just cutting the boards and let people do the soldering. I don't want to try to make hundreds and hundreds, but it doesn't seem like that would be necessary.

Let me know what people think and what the interest level is.